How-to-guide: Driving Growth in the Food Processing Equipment Manufacturing Industry 2021 - 2030

How-to-guide: Driving Growth in the Food Processing Equipment Manufacturing Industry

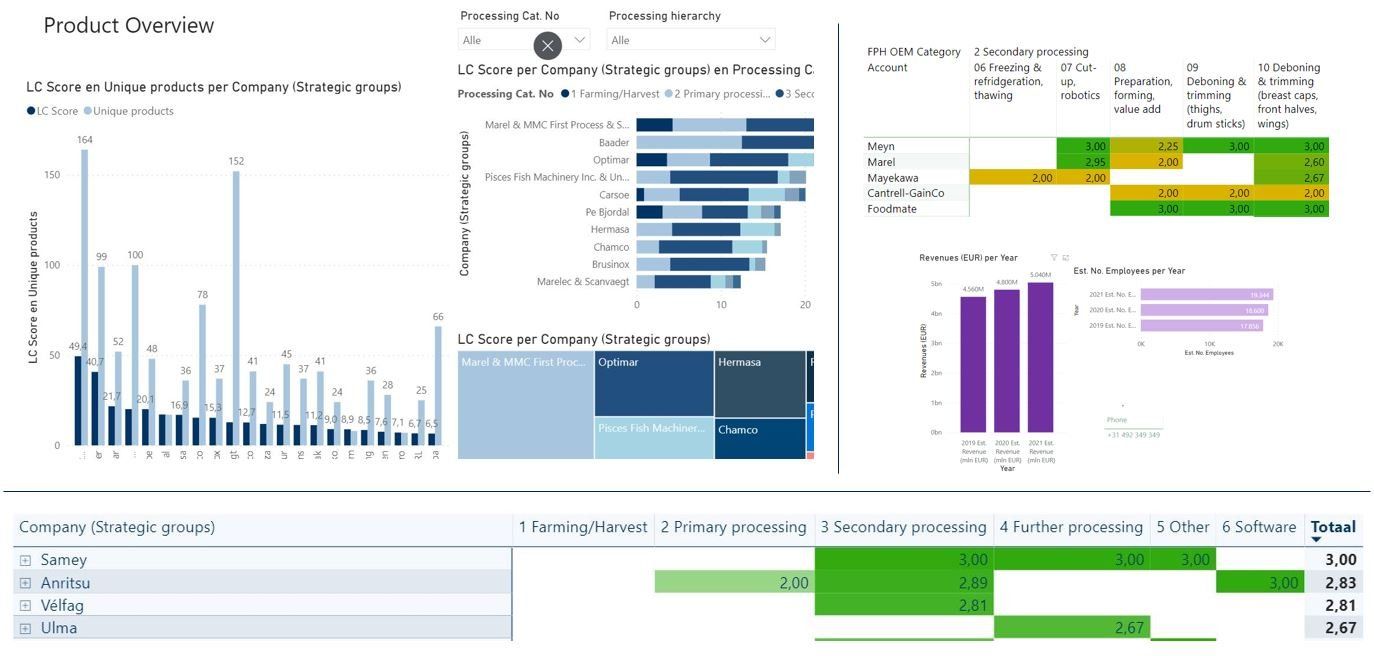

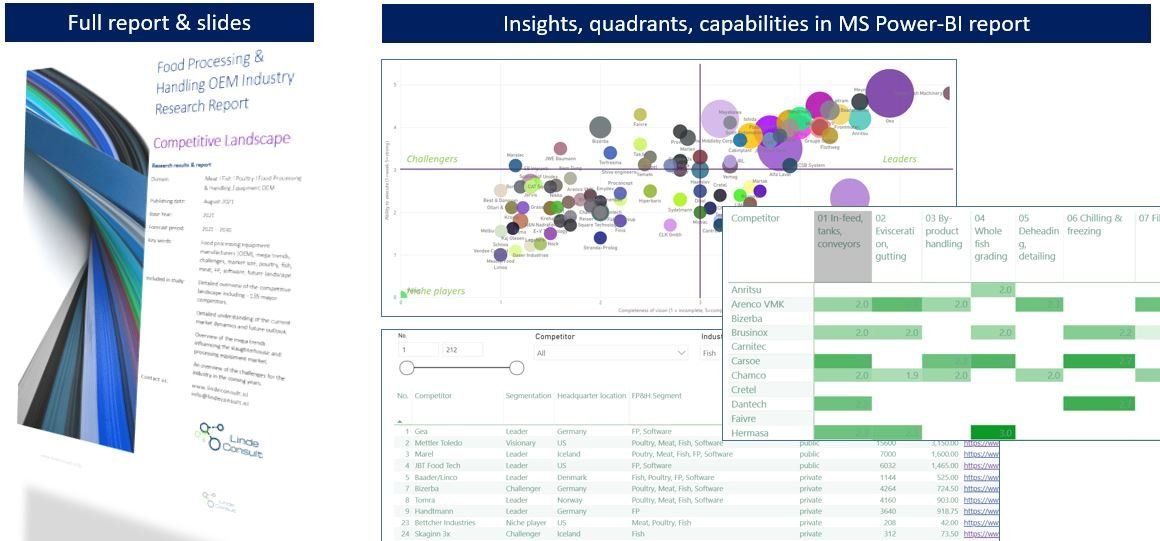

Early 2020, Linde Consult started an extensive research project with the objective to create a full insight in the competitive landscape of the 100 most prominent manufacturers of food processing & slaughterhouse equipment in the industries of Fish, Meat and Poultry (see here).

Research results

Besides describing, analysing and presenting conventional market data such as company size, turnover, number of employees, product portfolio and head quarter location we mapped the relative competitive power of the big-100 (using strength of vision, and ability to execute as coordinates) and presented current trends and challenges that influence how manufacturers develop their business. The research results are in fact the recipe for growth in the food processing equipment manufacturing industry.

How trends influence growth

One of the main findings of the research are that currently, technological and economical mega-trends affect the Food Processing Equipment Manufacturing Industry most. Political, Sociological and Environmental trends also play a role but have less impact on growth so we focus on technologic and economic trends in this how-to-guide. Factually, trends have the power to influence a whole industry, forcing the complete set of competitors into a certain direction with regards to product & business development.

Not surprisingly, the technological trend has a big impact on the equipment manufacturers thanks to new Industry 4.0 functionality becoming readily available, and thanks to customers now demanding more digitalisation and automation in products, services, and solutions that are a combination of both products and services. This drives the development of connected ‘smart’ equipment.

In parallel, the economical trend drives manufacturers to develop new business models with focus on outcome-based services that have become available and deliverable with the new technologies they developed as a result of the technological trend.

Combining the two strongest trends (blending new technology-driven services with a new service-delivery business model) is currently the juiciest recipe for growth in the Food Processing Equipment Industry.

How can your manufacturing business drive growth?

What can you do right now to capitalize on these new insights? How can you drive growth?

- To follow the technological trend, think about starting initiatives around integration of smart sensors in critical parts and equipment; connecting client-site equipment to the internet; and collecting, analysing and enhancing big data from Installed Base to name a few.

- To follow the economical trend, think about how to adapt or develop your business model so customers pay for a service contract including SLAs (service level agreements on uptime, performance, and outcomes); explore leasing of equipment instead of selling it; and investigate how you could provide valuable data & knowledge to your customer with dashboards showing enhanced data on uptime & performance; applying data mining and algorithms to find and predict patterns on e.g. wear & tear of critical parts; and development of new remote service capabilities and pricing strategies.

Of course, changing your organization is never easy and you should prepare for a lot of strategy work and fulfilling prerequisites. Don’t let it stop you! Start to identify your low hanging fruits and go from there.